Programme

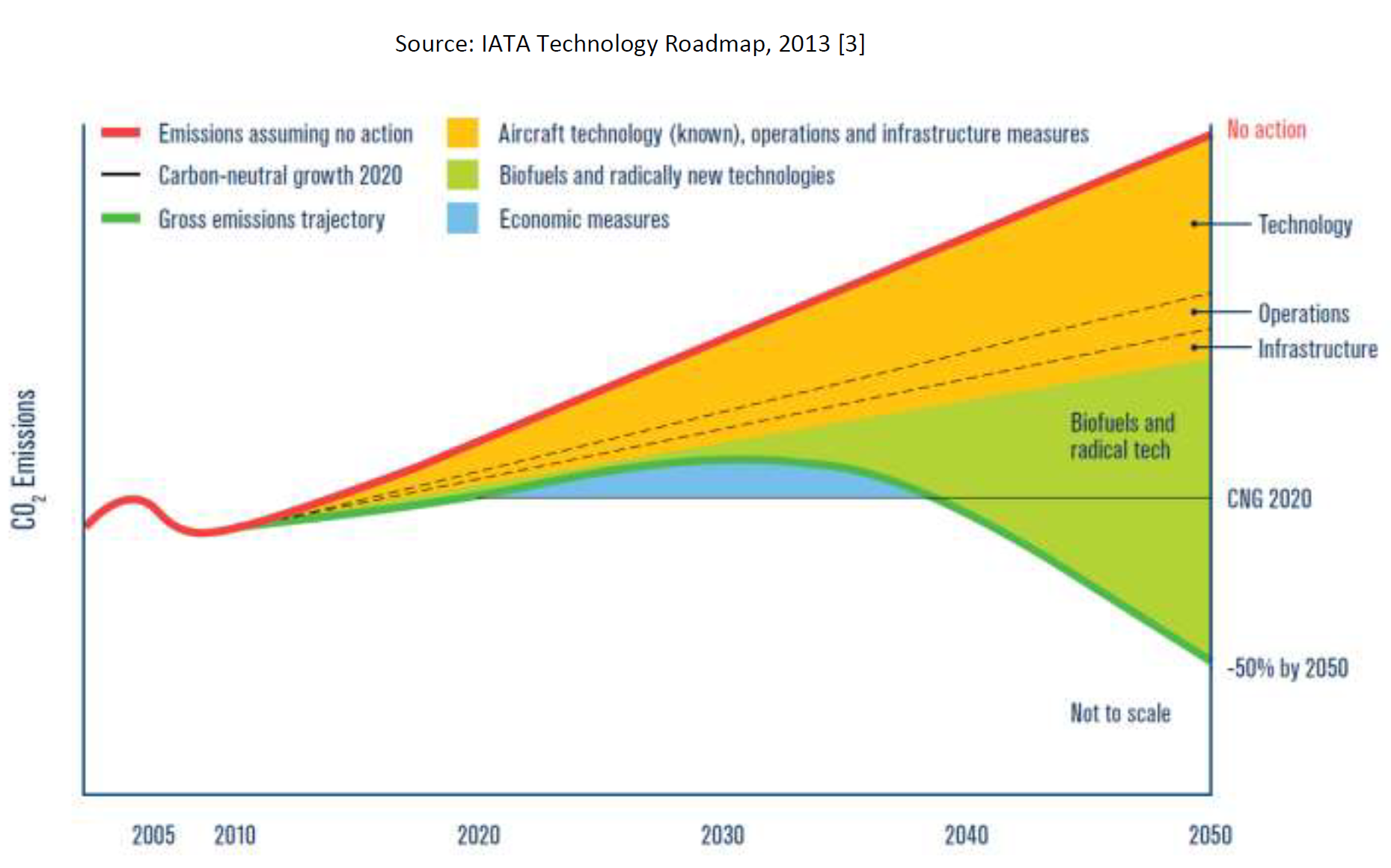

Aviation is facing public and governmental pressures to reduce its carbon footprint. These have been codified in regulations such as the European Commission’s Flightpath 2050 and others, and hence set targets which must be met by OEMs, commercial and infrastructure operators.

IATA plans show that meeting these regulations will require different solutions, including changing flight operations, new fuels, carbon offset, electrification, and many more.

Solving C02

In terms of aircraft propulsion, studies have shown that new technologies will be required to electrify larger and / or heavier aircraft. Current and proposed electric technologies just will not deliver high enough power densities within a wider power system suitable for aircraft.

Technology Solutions

Machines – motors and generators – built using superconducting technologies can theoretically deliver the MW power systems aircraft require. But they also bring their own problems for application to aircraft propulsion.

A couple of projects aim to build demonstrators to prove the theory, and examine the system / aircraft integration problems.

The EU’s Advanced Superconducting Motor Experimental Demonstrator project (ASuMED) aims to “demonstrate benefits and technological feasibility of a fully superconducting 1 MW motor with power density of 20 kW/kg”. Partners include KIT, Oswald, Rolls Royce, Cambridge University, University of Aschaffenburg, Air Liquide, Demaco, SuperOx, and IEE Bratislava. As of 2020, the project had developed new concepts of stator and rotor based on HTS materials, created dedicated cryocooling systems and cryostats, developed innovative modular inverter topologies, and assembled the motor for testing.

The TELOS project will “develop a develop a 10 MW generator using DC coils made of 2nd generation superconducting materials to provide a new technology for motors and generators with high power densities greater than 20 kW/kg, weighing less than 500kg”. The project involves Airbus, Rolls Royce (Siemens), KIT, TU München, and Neue Materialien Bayreuth. As of 2020, TELOS had identified materials for all components, developed a new electron beam welding process and validated the quality with tensile tests at 77 K, developed and validated processing and assembling of the generator, and demonstrated efficient manufacturing of the generator.

SuperOx Yak-40

An integrated HTS based 500 kW electric power system is being developed by the Foundation for Advanced Research and CJSC “Superox” in Russia, consisting of a battery, and HTS cable, current limiting device, and electric motor. The project has passed a set of ground tests, and was successfully test flown in 2021 in a flying laboratory based on a Yak-40 aircraft in 2021.

International Steering Committee for EFATS Workshop Series

James Fesmire

H2Gen

Prof. Sastry Pamidi

Center for Advanced Power Systems, Florida State University, & FAMU-FSU Engineering, Florida A&M; University

Dr. Shirley Pei

Bath University, Centre for Sustainable Power Distribution

Min Zhang

University of Strathclyde, Applied Superconductivity Laboratory

Prof. Sandy Smith

University of Manchester, Rolls-Royce UTC on Electrical Systems for Extreme Environments

Dr Ludovic Ybanez

Airbus UpNext, Head of ASCEND demonstrator & Managing Director of Airbus ExO Zero Emission SAS